End of Summit

The 16th InBiGeGa Forum was successfully held by Asian Metal in Ningbo, China on March 29, 2024. The Forum covered broad topics including upstream raw material supply, production, consumption, trading and price trend prediction on indium, bismuth, germanium and gallium. This Forum gained broad support from minor metals industry professionals, and representatives from countries and regions including China, Germany, the U.S.,Taiwan and so on took part in the Forum.

Event Registration

Event Registration

Event Registration

Event Registration

Event Registration

Event Registration

Event Registration

Event Registration

The Forum started at 9:00 a.m. on March 29.

Ben Jiang, Content Director of Asian Metal

Conference Site

First, Mr. Genbao Xu, a distinguished expert of the National Thousand Talents Program, made a wonderful presentation titled Application of CIGS cell Technology and Thin-film cell in Photovoltaic Buildings. His presentation was composed of five sections, including types and technical upgrading of solar battery, CIGS cell production process and technical challenges, CIGS cell conversion efficiency enhancement, properties and product development of CIGS cell , and CIGS power generating parts and applications. After introduction on major types and respective characteristics of solar cells, Mr. Xu introduced CIGS cell characteristics including no pollution, low costs and high conversion efficiency. Next, he outlined broad application horizon of CIGS cells with real cases from technical perspectives. Xu Genbao is a distinguished expert for China's Thousand Talents program and Float Glass Key Laboratory. Moreover, he is a distinguished guest professor for China's Green Building Material Key Laboratory and a part-time professor in the Material Science Department of the University of Science & Technology Beijing, as well as a member of SEMI China. He has gained considerable and invaluable experience in the R&D and industrialization of production equipment of solar cell and semiconductor.

Genbao Xu, Distinguished Expert of the National “Thousand Talents Plan”

Genbao Xu, Distinguished Expert of the National “Thousand Talents Plan”

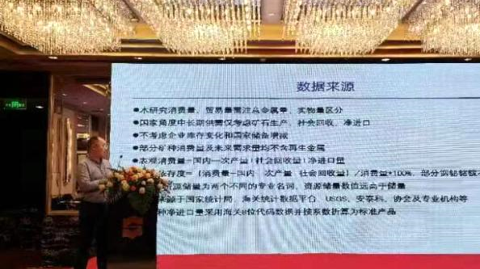

Immediately afterwards, Mr. Qunyi Liu, the director of Basic Mineral Strategy Research Office, Research Center for Global Mineral Resources Strategy, Chinese Academy of Geological Sciences, gave a detailed explanation of the "Medium and Long-term Demand Trends and Resource Supply of Indium, Bismuth, Germanium and Gallium". Mr. Liu discussed from three dimensions: "current supply and demand situation of indium, bismuth, germanium and gallium", "medium and long-term demand trend of indium, bismuth, germanium and gallium" as well as "medium and long-term supply capacity of indium, bismuth, germanium and gallium". He mentioned that China's reserves of these four minerals rank first in the world and its per capita reserves are higher than the world average, while in terms of import and export, these four minerals are all net exports. In the domestic consumption structure, the ITO target field accounts for 85% and still dominates the indium market; in terms of bismuth, with the continuous advancement of technology and the iterative upgrade of consumer demand, bismuth will generate more new applications and new demands in more fields; for germanium, military, aerospace, maritime and other fields place more emphasis on the performance of infrared devices, and the demand for germanium in the infrared field still maintains a slight growth trend; as for the demand side of gallium, my country's gallium consumption power will come from magnetic materials and compound semiconductor fields in the future. Qunyi Liu, Associate Researcher, current Director of Basic Mineral Strategy Research Office, Research Center for Strategy of Global Mineral Resources, Chinese Academy of Geological Sciences (CAGS) and China Geological Survey (CGS), mainly engaging in the study and research on resource allocation, industrial development, supply and demand of bulk minerals, including ferrous metals, non-ferrous metals and nonmetals in global and domestic markets, giving strategic recommendations and policy proposals to the state. He also presided over multiple high-level strategic research reports on major national needs in recent years.

Qunyi Liu, Director of Basic Mineral Strategy Research Office, Research Center for Global Mineral Resources Strategy, Chinese Academy of Geological Sciences

Qunyi Liu, Director of Basic Mineral Strategy Research Office, Research Center for Global Mineral Resources Strategy, Chinese Academy of Geological Sciences

Tea break

Tea break

Next, Mr. Cheng Zhang, deputy chief engineer of DEC (Leshan) Eban High Purity Materials Co., Ltd., delivered a wonderful speech on "Development and Application of High-purity Tellurium and High-purity Indium Technology". Mr. Zhang focused on "current status of the development of high-purity tellurium technology", "application and market prospects of high-purity tellurium", "current status of the development of high-purity indium technology", "application and market prospects of high-purity indium" as well as "importance of high-purity materials" to share his views. DEC (Leshan) Eban High Purity Materials Co., Ltd. is the pioneer company engaged in the research, development and production of high-purity metal and compound semiconductor materials in China and owns a modern thousand-level purification plant, a hundred-level ultra-clean room as well as the country's leading GDMS and ICPMS testing equipment. Over the years, the variety number of high-purity metal and semiconductor materials it has developed and produced ranks first in the country. The company's main products are divided into three categories: elemental elements, compounds and oxides, covering 99.999%-99.999995% tellurium, cadmium, antimony, gallium, indium, tin, zinc, silver, cadmium-zinc-telluride and other high (ultra) pure material. Its products are widely used in infrared, photovoltaic, new energy, thermoelectric, medical, electronic refrigeration components, integrated circuits, semiconductors, alloys and other industries, and play a vital role in the high-tech field, providing key materials for China's essential equipment.

Cheng Zhang, Deputy Chief Engineer, DEC (Leshan) Eban High Purity Materials Co., Ltd.

Cheng Zhang, Deputy Chief Engineer, DEC (Leshan) Eban High Purity Materials Co., Ltd.

The finale report of the morning session was the "Application and Outlook of Germanium in Infrared Industry" shared by our old friend Dr. Christian Hell, general manager of IV IR Optics. After briefly introducing the history and milestones of IV IR Optics in Germany, Dr. Hell began to review with everyone the germanium demand, price trends, current research status, and market situation. Given that around 90% of the 135tpa global germanium metal production come from China and the market demand grows up gradually at present, he hoped that the price trend would become more stable, which would benefit the entire industry chain. He noted that the current germanium production is increasing, and both China and overseas demand are rising. China's implementation of export controls has led to changes in the supply situation. The market tends to bypass China's supply chain. However, nearly 90% of the world's germanium production comes from China, and how to solve the above problems has become the primary problem. The importance of recycling and alternative sources has been highlighted increasingly and the industry is paying great attention to it. IV IR Optics is dedicated to manufacturing highest quality germanium and silicon material and precision components for infrared optics applications. Their advanced production and measuring technologies and equipment guarantee consistent and cost effective processes and outstanding product quality. As a reliable and flexible partner they help customers to increase their production efficiency with short lead times, support of Kanban principles and high precision blanks to save manufacturing cost.

Christian Hell, General Manager, IV IR Optics

Christian Hell, General Manager, IV IR Optics

The forum continued after lunch. First of all, Mr. Yinghan Bu, chief engineer of Zhejiang Compound Semiconductor Co., Ltd., gave a keynote speech on the Application and Market Development of GaAs Materials. He first made a brief introduction to GaAs, and then introduced the application fields of GaAs in detail. GaAs has important application value in the field of optoelectronic devices. He stated that the global sales of two-inch GaAs substrates in 2019 were approximately 20 million pieces, and it is expected to exceed 35 million pieces by 2025, with a comprehensive average growth rate of 9.72% from 2019 to 2025. The global GaAs substrate market size in 2019 was about 200 million US dollars, and it is expected to reach 348 million US dollars by 2025. Zhejiang Compound Semiconductor Co., Ltd. was established on November 5, 2018, with a business scope of R&D, production, and sales of GaAs materials. The company is mainly jointly invested by Beijing Junpeng Bu Team (investment, technology, operation), Xiamen Changelight Co., Ltd., and Anxin Fund (investment). The company has completed Series A financing with a post-investment valuation of 700 million yuan (96.74 million US dollars). At present, semi-insulating GaAs substrate materials in China rely entirely on imports. Compound's products benchmark against Sumitomo in Japan, achieving import substitution and filling the gap in GaAs substrate materials for domestic RF chips. The product has been sold to Epistar. Compound's domestically produced semi-insulating products, which rely entirely on imports, have entered the international market and have promising future prospects. In addition, Compound's GaAs chips are supplied to downstream manufacturers, and through reproduction, they are mainly used in Huawei's facial recognition terminal products. Compound has become an upstream supplier of Huawei's industrial chain.

Yinghan Bu, Board Chairman, Zhejiang Compound Semiconductor Co., Ltd.

Yinghan Bu, Board Chairman, Zhejiang Compound Semiconductor Co., Ltd.

Subsequently, Mr. Xiaohua Huang, Chairman of Shaanxi Injay Semiconductor Co., Ltd., gave a keynote speech on Market Application and Industry Outlook of InP. He introduced that InP has the characteristics of high electron mobility, wide bandgap, high temperature resistance, and strong radiation resistance. It is widely used in fields such as aerospace, satellite communication, THz, lasers, solar cells, photodetectors, and fiber optic network systems. Injay Semiconductor is a high-tech company dedicated to the research and industrialization of compound semiconductor materials. Focusing on the industrialization implementation of high-quality InP polycrystalline semiconductor materials, this project fulfilled the zero breakthrough in the industrialization of high-quality InP polycrystalline materials in China. The company has a complete set of equipment, processes, and control systems with independent intellectual property rights, and has a highly integrated automated mass production capacity for InP polycrystals. The quality of InP polycrystals produced by Injay has reached the international advanced level, with high consistency and stability in various indicators.

Xiaohua Huang, Board Chairman, Shaanxi Injay Semiconductor Co., Ltd.

Xiaohua Huang, Board Chairman, Shaanxi Injay Semiconductor Co., Ltd.

After the tea break, Mr. Zewei Fu, Deputy General Manager of Yunnan Tin New Materials Co., Ltd. gave a wonderful speech on Promising Future of High-purity Small Metals. Mr. Fu shared the overview of the industry chain, the preparation technology and the application of high-purity small metals. Yunnan Tin New Materials Co., Ltd. is a wholly-owned state-owned subsidiary of Yunnan Tin Group (Holding) Co., Ltd. and Yunnan Tin Co., Ltd. is a shareholder. It mainly engages in the production, sales, research and development trade of tin and indium deep processing products, and is committed to becoming the most competitive tin and indium new materials and deep processing enterprise in the world. The company has two industrial sectors: tin material and tin chemical industry. The tin chemical industry sector has two major series of inorganic tin and organic tin, 28 varieties, and 45 specifications of products, with an annual production capacity of 26,000 tons. The tin material sector has nine major series, including bars, wires, powders, pastes, bar sections, granules, balls, and hemispheres, and more than 1,000 specifications of products, with an annual production capacity of 40,000 tons. The company independently developed a series of high-purity materials, targets, flame retardants, preformed solder pads, and other products, including high-purity indium, high-purity indium oxide, and high-purity tin oxide. The company has national postdoctoral research workstations, Yunnan Tin Materials Engineering Technology Research Center, Yunnan Tin Chemical Engineering Technology Research Center, Yunnan Indium Engineering Research Center and other platforms. The company is a national high-tech enterprise, an enterprise technology center of Yunnan Province, and a quality benchmarking enterprise.

Zewei Fu, Vice General Manager, Yunnan Tin New Materials Co., Ltd.

Zewei Fu, Vice General Manager, Yunnan Tin New Materials Co., Ltd.

Finally, Mr. Zhiqiang Huang, the General Manager of Foshan Qingzhou Metal Co., Ltd., delivered a wonderful speech on Exploration of China's Selenium and Bismuth Industry Trends and Potential. Mr. Huang made analysis based on status quo of selenium industry, noting that manganese flake industry is still the largest consumption industry for selenium with a proportion of 43% or so and the second and third consumption industries are glass & ceramics industry and feed & agriculture industry with a proportion of 23% and 22% respectively. Selenium is usually used to produce sodium selenite and selenic acid salts in feed industry and selenium fertilizer for selenium-containing crops in agriculture. The current selenium consumption volume in producing sector is around 600t with a rapid increase in China in the recent two years. As for PV industry, selenium is a major raw material to produce CIGS thin film solar cells, while the consumption volume for selenium in other fields hasn't increased substantially in recent years. Mr. Huang believes that the heterogeneous HJT photovoltaic cell modules in the new application field of bismuth are more likely to become the mainstream of photovoltaic power generation in the future due to high efficiency. The production capacity of HJT modules rose by 60GW in 2023 and is expected to increase further by 100GW in 2024. One of the raw materials for low-temperature welding ribbon used in HJT modules is tin-bismuth alloy Sn42Bi58 and it's expected that the bismuth ingot consumption would increase by 2,500-2,800t in 2024 calculated based on that 1GW of HJT modules will consume 400-450t of low-temperature welding ribbon, 1t of low-temperature welding ribbon will consume 180kg of low-temperature tin solder material and 1t of tin solder material will consume 580kg of bismuth. Founded in 2000, Foshan Weijun Nonferrous Metals Co., Ltd. has been awarded the title of Contract Abiding and Creditworthy Enterprise in Guangdong Province for 21 consecutive years. The company mainly does business of rare and scattered-distribution nonferrous metals and rare earth alloys, and produces refined selenium used in industrial production, and selenium dioxide. It also develops and produces organic selenium and nano selenium fertilizer and the nano selenium fertilizer dependently researched and developed by the company itself has been widely applied in agriculture field, playing a proactive role in improving output and quality of crops and raising revenues in agriculture.

Zhiqiang Huang, the General Manager of Foshan Qingzhou Metal Co., Ltd.,

Tea break

Photo

Photo

Photo

Photo

Photo

Photo

Photo

Photo

Photo

Photo

As time flies, the In Bi Ge Ga Forum held by Asian Metal is now in its 16th year. The successful hosting of each forum has been inseparable from the strong support and participation of every industry insiders. Asia Metal will continue to reflect the true operating conditions of the market timely, objectively and accurately, striving to provide every clients with information of highest value to help them make market decisions. We will live up to the over 20 years of trust and support from clients both at home and abroad. Let's work hand in hand and meet again next year! The 16th In Bi Ge Ga Forum has come to a successful close.

Dinner

Dinner

Dinner

Dinner