End of Summit

Asian Metal held 13th International Rare Earth Summit successfully in Hangzhou, Zhejiang province on 22-23 September 2023. The summit was sponsored by Aclara Resources Inc. and contained topics of rare earth ores in Latin America, the United States and Australia, Chinese monazite market, NdFeB magnet industry, rare earth magnesium alloy market, the application of rare earth in electric vehicle and glass industries. The summit was widely supported by rare earth participants, with nearly 200 representatives from home and abroad attending.

Sign in

Sign in

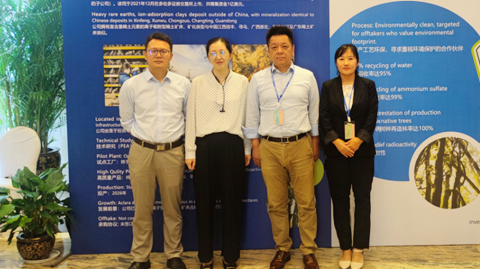

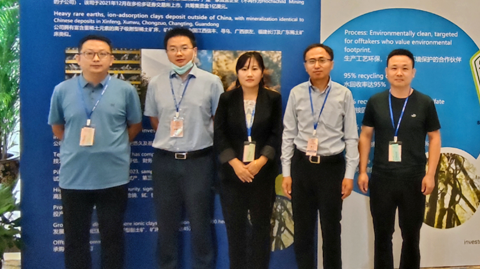

The summit started at 9:00 a.m.of 23 September 2022. Mr. Ramón Barúa, CEO of Aclara Resources Inc. delivered the opening speech on line. Afterward, Mr. Ramón Barúa made a speech on line on “Powering Our Electric Future”. Mr. Ramón Barúa explained the competitive advantages of ionic rare earth concentrate. He noticed that rare earth plays key role in the electric revolution and heavy rare earth demand would climb sharply in the coming years but the supply would become insufficient. Mr. Ramón Barúa forecasted that the global electric vehicle demand and off-shore wind turbines installations would increase with CAGR of 30% and 20% respectively from 2022-2030. Mr. Ramón Barúa introduced their Penco project, which mineralization identical to Chinese deposits in Xinfeng, Xunwu, Chongzuo, Changting, Guandong. The Company already finished an economic evaluation with positive financial results. The company’s pilot plant would start production in Q2 of 2023 and plans to delivery sample in Q3 of 2023. Their ionic rare earth concentrate contains 92.6% of TREO, including 5.5%,0.7%,12.5% and 2.9% of dysprosium, terbium, neodymium and praseodymium respectively. Their products contain no radioactivity. The company aims to start commercial production in 2026.

Conference room

Ramón Barúa, CEO of Aclara Resources Inc gave presentation online

Conference room

Ramón Barúa, CEO of Aclara Resources Inc gave presentation online

Afterwards, Kaihong Ding, General Manager of Yantai Dongxing Magnetic Materials Inc. gave a speech on “Review & Prospect of Industrialization of High-performance NdFeB Permanent Magnet”. Mr. Ding reviewed the industrialization of high-performance NdFeB permanent magnet. According to Mr. Ding, NdFeB magnet was not seen having a bright future in the past, but owned the basis of industrialization through hard work and adding heavy rare earth elements and other methods to improve coercivity. In 2000, SC alloy technology improved the consistency and stability of NdFeB magnet greatly. Hydrogen Treatment Technology ensured grain integrity of SC alloy during pulverization, improved the magnetic properties and brought great changes and progress to the NdFeB magnet industry. Subsequently, the low oxygen process and heavy rare earth diffusion technology further promoted the development of the NdFeB magnet industry. Mr. Ding also looked forward to the application prospects of high-performance sintered NdFeB permanent magnet materials in the fields of new energy vehicle drive motors, air conditioner compressors, and wind power generation.

Kaihong Ding, GM of Yantai Shougang Magnetic Materials Co. made speech

Kaihong Ding, GM of Yantai Shougang Magnetic Materials Co. made speech

Afterwards, Huibo Wang,Deputy General Manager of CNNC Rare Materials Co. introduced the development of Chinese Monazite Comprehensive Utilization Industry and looked forwarded the prospect of the industry. Mr. Wang disclosed that monazite mainly bases in China, Australia, Brazil, the United States and so on. Monazite contains 0.3-0.6% of U3O8 and 5-8% of ThO2 and could be used as the raw material of extracting uranium and thorium and owns radioactivity. In February of 2013, China’s Ministry of Environmental Protection released 《Catalogue of Radiation Environmental Supervision and Management for Mineral Resources Development and Utilization (the first batch)》for effective implementation of supervision. The catalogue clearly lists the mining, beneficiation and smelting of monazite in the first list of radiation environmental supervision and management. China has banned the mining of monazite, and monazite in China mainly comes from the by-products of beneficiation of imported (or domestic) zircon sand. Hunan Zhonghe Jinyuan New Material Co., which is subsidiary of CNNC Rare Materials Co., is the only company that owns qualification to dispose acid dissolved slag of monazite in China. The company produces rare earth chloride by leaching, separating and recycling acid dissolved slag of monazite and its recovery rate of rare earth, uranium and thorium records as high as more than 95% with safe recovery of radioactive resources. Presently, the company owns an annual consumption volume of around 18,000t of monazite and an annual output of about 15,000t of rare earth chloride.

Huibo Wang, Deputy GM of CNNC Rare Materials Co. delivered speech

Huibo Wang, Deputy GM of CNNC Rare Materials Co. delivered speech

Tea break

Tea break

After the tea break, Mr. Pol LE ROUX, Sales & Marketing, Innovation & Technology, Downstream Industrial Operations Vice President of Lynas Rare Earths, LYNAS USA President gave speech by online. Mr. Pol LE ROUX introduced Lynas Sustainable Growth Plan. According to him, global NdFeB magnet demand climbed by 16% YoY in 2021. He forecasted that the global NdFeB magnet demand in 2022 and till 2030 will increase by about 20% YoY and doubled from now. Lynas plans to enlarge production capacity continuously in the coming 2-3 years. The company plans to set up mixed rare earth carbonate processing plant in Malaysia and intends to increase PrNd oxide production capacity to 10,500t/y. The company aims to enlarge their Mt Weld project in order to meet the demand of 12,000t per year of concentrate. The company’s plant in the United States will start production from 2025.

Pol LE ROUX, Sales & Marketing, Innovation & Technology, Downstream Industrial Operations Vice President of Lynas Rare Earths, LYNAS USA President made speech online

Pol LE ROUX, Sales & Marketing, Innovation & Technology, Downstream Industrial Operations Vice President of Lynas Rare Earths, LYNAS USA President made speech online

Afterwards, Mr. Yi Dong, Deputy GM of Baotou Tianhe Magnetics Technology Co. made a speech on “Status and Prospect of NdFeB Magnet Industry and Technology”. According to Mr. Dong, China’s NdFeB magnet output in 2021 reached approximately 220,000t. He holds an optimistic attitude towards NdFeB magnet demand outlook and predicted that NdFeB magnet demand from new energy vehicles, industrial motor and robot industries would climb sharply. Mr. Dong also introduced that current Chinese domestic NdFeB manufacturers are gradually concentrating on the origin of raw materials. Overseas participants are trying to develop local rare earth supply chains. Current NdFeB magnet industry technology development trend are heavy rare earth diffusion technology, heavy rare earth free technology and high abundance rare earth replacement technology such as lanthanum and cerium.

Yi Dong, Deputy GM of Baotou Tianhe Magnetics Technology Co. gave speech

Yi Dong, Deputy GM of Baotou Tianhe Magnetics Technology Co. gave speech

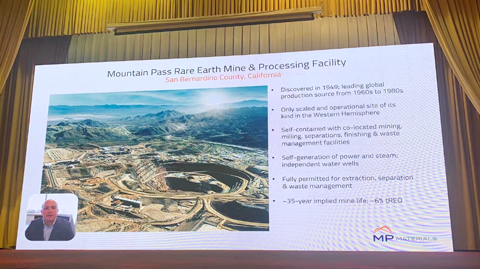

At around 2:00pm, Matt Sloustcher, Sr. Vice President, Communications & Policy of MP Materials Corp. made report online. According to Mr. Matt Sloustcher, MP Materials Corp.is trying to integrated rare earth supply chain in the United Sates. The company is developing into a large, vertically integrated materials and magnetics producer. Mountain Pass was discovered in 1949 and owns mining lift of 35 year. The mine was a leading global production source from 1960s to 1980s and owns TREO of 6% and is the only scaled and operational site in the Western Hemisphere. The mine is self-contained with co-located mining, milling, separations, finishing & waste, management facilities. The mine owns self-generation of power and steam. The mine recovers more than 1.7 billion litres of water per year from tailings, which meets 95% of beneficiation need. MP Materials Corp. plans to start producing light rare earth oxide from late 2022 and aims to produce around 6,075t of PrNd oxide in 2023.

Matt Sloustcher, Sr. Vice President, Communications & Policy of MP Materials Corp. made speech online

Matt Sloustcher, Sr. Vice President, Communications & Policy of MP Materials Corp. made speech online

Whereafter, Stephen J. Maguire, Principle Engineer of Bose Corporation delivered a presentation on “Rare Earth Magnet Demand Trends”. Mr. Stephen J. Maguire claimed that their end users pay close attention to the stability of rare earth and NdFeB magnet prices. He believes that government mandated policies to combat global warming will be the primary force driving the growth of the global NdFeB industry from 2021 to 2030. He forecasted that the NdFeB magnet demand from electric vehicles and offshore wind power industries will climb sharply from 2021 till 2030. New regulatory targets in the European Union and the United States now aim for an EV share of at least 50 percent by 2030, and several countries have announced accelerated timelines for ICE sales bans in 2030 or 2035. The average hybrid or electric vehicles uses between 2 and 5Kg of NdFeB Magnets. He believed that the deployment of global offshore wind energy will accelerate in the future. Some organization forecasted sevenfold increase in global cumulative offshore wind capacity to 215 GW or more by 2030. Many experts pointed out that NdFeB magnet demand has to increase with a compound annual growth rate of 4-5% in order to support the zero-carbon plan of Western countries. Mr. Stephen J. Maguire believed that a healthy balance of magnet supply chain profit and downstream industry profit, is important.

Stephen J. Maguire, Principle Engineer of Bose Corporation gave lecture online

Stephen J. Maguire, Principle Engineer of Bose Corporation gave lecture online

Later, Joanna Jia, Vice president& Marketing Director of Hangzhou Permanent Magnet Group Co. gave a speech on “Magnets for Green Future”. Ms. Jia said they permanent magnet motors consume less energy, which results reducing carbon dioxide emissions. The carbon footprint of permanent magnet motors is less than asynchronous motors of the same power. Although the production and consumption of NdFeB magnet is environmentally friendly, we could make NdFeB magnet become more environmentally friendly. The current consensus is that the production of 1kg of NdFeB magnet would bring 25-30kg of carbon dioxide. Although the change of using renewable energy,the implementation of Waste minimization during cutting, slicing section and the improvement of recycling rate of every production section, and increase the recycling of waste magnet and so on, could continue reducing the carbon footprint.

Joanna Jia, Vice president& Marketing Director of Hangzhou Permanent Magnet Group Co. gave presentation

Joanna Jia, Vice president& Marketing Director of Hangzhou Permanent Magnet Group Co. gave presentation

Tea break

Tea break

After the tea break, Shengteng Yang, General Manager of Longnan Longyi Rare Earth Materials Co. gave a speech on “Promote the Development of Rare Earth Special Steel and Rare Earth Magnesium Alloy Industries”. According to Mr. Yang, magnesium alloy owns advantages of low mechanical properties, poor heat and corrosion resistance. Rare earth is the indispensable element to solve the disadvantages of magnesium alloy. But the engineering application and industrialization of rare earth magnesium alloy in China are not optimistic, only limited to some high-end applications and military applications. The main problems in the China rare earth magnesium alloy are as below: 1. Cooperation between midstream and downstream is not close enough and technical barriers exist. 2.Limited consumption volume and extremely high costs restrict the development of rare earth industry. 3.Only limited varieties of rare earth products are supplied and the quality is low. 4.Owing to backward production technology and low ability in testing, the homogeneity of rare earth products couldn't be ensured. 5.Downstream users just consider rare earth producers as suppliers and rare earth producers are inactive in developing low-cost and high-quality rare earth magnesium intermediate alloy. In order to boost the development and application of rare earth magnesium alloy and solve the bottleneck problems related to the application of rare earth in magnesium alloy field, Longnan Longyi Heavy Rare-Earth Technology Co. gives full play to its advantages in upstream and midstream rare earth industries and extends its industry chain to build a rare earth magnesium alloy industry chain.

Qing Yang, President of Longnan Longyi Rare Earth Materials Co. made a speech

Tea break

The last speaker of this summit was Taowei Wang, Sales Director of Deyang Hongyuan Ceramics Material Co. The topic of Mr. Wang was “Analyze the Application of Rare Earth in Glass Industry”. Mr. Wang elaborated on the classification of glass and glass products, the application of rare earth in glass industry, the influence of rare earth price on glass industry and the application prospect of rare earth in glass industry. According to Mr. Wang, cerium oxide and lanthanum oxide were widely used in glass clarification and glass decolorization industry. Cerium oxide 99.9%min owns advantages of environmentally friendly, high economic benefits and so on. In the production of glass decolorization, cerium oxide 99.9%min owns the high economic and social benefits. Mr. Wang foresaw gradually increasing demand of cerium oxide and lanthanum from glass industry.

Taowei Wang, Sales Director of Deyang Hongyuan Ceramics Material Co. gave a speech

Group photo

Group photo

Group photo

Group photo

Group photo

Group photo

Group photo

Group photo

Group photo

Group photo

Business group photo

Dinner group photo

Dinner group photo

Dinner group photo

Dinner group photo